Cellphone:

0086-13906587665(Donna)

E-mail: hongxin17@hxtwheel.com

Add: Food Area, Huangyan Economic Development Zone, Taizhou, Zhejiang, China.

RAW MATERIAL TESTING AND CUTTING

Before cutting the aluminum bars, overall testing is strictly made to ensure the quality of raw material from the very beginning.

MATERIAL PREHEATIN

Before forging process, the aluminum bars are heated in the box-type continuous furnace to reach the best malleable temperature.

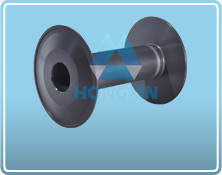

FORGING

Forging process enables the sterepsinema to reach the smaller fibrous grains, while deficiencies in the aluminum alloy can be addressed, which will enhance the mechanical properties and strengths.

HEAT TREATMENT

Through heat-treatment and high temperature solution treatment, internal structure of aluminum alloy sterepsinema becomes more stable, which will once again raise the sterepsinema’s mechanical strength and hardness.

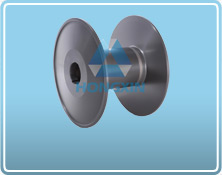

MACHINING

The final formation of forged beam takes place in the machining process where it goes through rough and finishing turning.

WELDING

Welded by the most modern automatic welding machine.

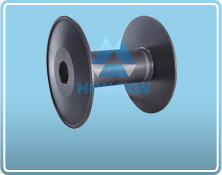

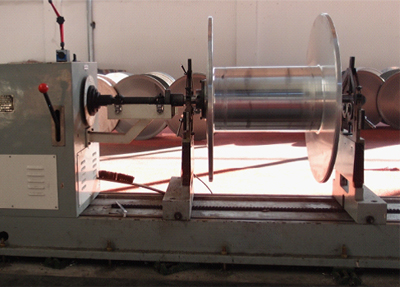

BALANCING

100% balanced by dynamic balancing machine after final machining.

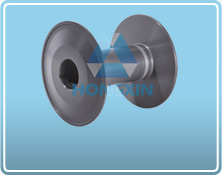

HARD ANODIZING

Hard anodizing coating treatment can prevent corrosion and surface scratching and increase hardness as well.